Get This Report on Solvent Recovery and Recycling2013.

An Unbiased View of Solvent-based separation and recycling of waste plastics

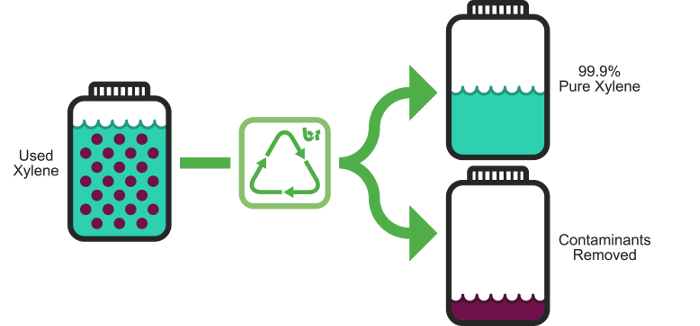

Solvent sludge is heated up to programed temperature level to produce vapor which exits boiler and takes a trip through condenser. Scrapper rotates at bottom of distillation vessel to keep it tidy and prevent calcination of chemicals. Entire process is controlled by PLC.Clean, condensed solvent exits to storage vessel prepared for reuse. If you can not find what you need or ask for a customized part, merely call and speak to among our well-informed ERG Environmental Provider professional.

2021 American Association for the Improvement of Science. All rights scheduled. AAAS is a partner of HINARI, AGORA, OARE, CHORUS, CLOCKSS, Cross, Ref and COUNTER.

Safety-Kleen provides a wide variety of cleansing devices and chemistries with unrivaled quality and efficiency. Our sales and service agents are geared up to work with you to develop the ideal parts cleaning up devices, chemistries, and involved service to satisfy your cleansing and environmental service requirements. Our parts washers are the only ones to earn NASCAR EFFICIENCY classification.

Solvent Recovery System - Solvent Recycling Equipment

Scrape-Sided Solvent Recycling System - SCR Distillation System - PRI

The Best Guide To Solvent Recovery and Recycling - SRS Engineering Corporation

Java, Script appears to be disabled on this computer. Please The Latest Info Found Here to see any active alerts.

Among the most typical procedures we see in the manufacturing industry is the application of paints, top coats, and primers utilizing an applicator spray weapon/ paint line. From an environmental reporting viewpoint, EHS professionals are normally well versed in how to calculate air emissions from the real paint application utilizing aspects like application effectiveness rate etc.

If you aren't effectively calculating the results of your solvent recycling procedure, you're most likely over-reporting on your air emissions; by comprehending how to manage and report solvent recycling, you'll have the ability to declare the appropriate air credits and your capability to track the impact of your manufacturing processes in general will improve.

Fractional Distillation and Solvent Recycling - B/R Blog - BR Things To Know Before You Buy

If you're asking yourself "what is TRI reporting?", the fast summary is that it is an EPA chemical reporting program that needs producers to report any TRI reporting chemicals they process, make, or otherwise use - if these quantities are above a defined EPA TRI reporting limit. In basic, many production facilities follow the same procedure for solvent use, healing, and recycling when it concerns paint lines and spray guns: As a paint weapon is used, it requires to be cleaned or flushed to get rid of any excess paint for maintenance and/or color modifications.